Lifecycle Assessment & Carbon Footprint

What is LCA?

A Life Cycle Assessment (LCA) is a comprehensive approach used to assess the environmental effects of a product throughout its entire life cycle. This includes every phase, from the extraction of raw materials and processing in the supply chain, to manufacturing, distribution, usage, maintenance, and ultimately, disposal.

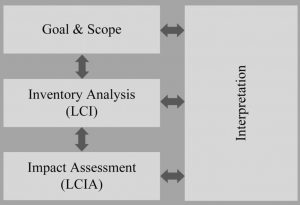

How to Conduct an LCA Project

We offer comprehensive support throughout the four key stages of an LCA project:

- Goal & Scope

We help kickstart the project by clearly defining the functional unit, reference flows, allocation methods, data collection strategy, and system boundaries. Typically, this phase takes half a day and can be conducted with a team of key stakeholders to ensure their involvement early in the process. - Inventory

We assist in structuring the LCA model and selecting the relevant data for your assessment. - Impact Assessment

We guide you in choosing the right impact indicators and characterization models to evaluate environmental effects. - Interpretation

We provide support in extracting critical insights and identifying the most significant sensitivities in your analysis.

LCA Stages according to ISO 14040

Why Do You Need LCA?

Conducting an LCA offers significant benefits for your business. The insights gained from LCA can support product development, enhance marketing strategies, inform strategic planning, and guide policymaking.

For instance, product designers can understand how their design choices influence the sustainability of the product. Policymakers can use LCA to compare the environmental impacts of various options.

Sustainability managers can evaluate their product portfolio and identify actions needed to meet carbon reduction targets. Marketing teams gain reliable data to back sustainability claims, while the purchasing department can identify suppliers with the most sustainable practices and products.

What is an EPD?

An Environmental Product Declaration (EPD) is a communication tool derived from a product’s Life Cycle Assessment (LCA). It presents the environmental impact of a product throughout its life cycle in an easy-to-understand format, making it accessible to a wide range of audiences. EPDs are based on scientific data, independently verified, and publicly available. They are often compared to nutrition labels on food products.

EPDs are available for a variety of products, including building materials, food items, consumer goods, and even equipment and devices.

For manufacturers, an EPD serves as a way to communicate the environmental performance of their products. For consumers or businesses looking to purchase, an EPD provides reliable environmental information to make informed decisions.

How Does an EPD Benefit Your Business?

As a Manufacturer:

An Environmental Product Declaration (EPD) helps you clearly communicate the environmental impact of your product to your customers. By providing verified, science-based data, an EPD differentiates your product in the market, showing your commitment to sustainability. This transparency can increase customer trust, help meet regulatory requirements, and give you a competitive edge, especially as more consumers and businesses prioritize eco-friendly products.

As a Consumer or Purchaser:

An EPD provides reliable, transparent environmental data that allows consumers and businesses to make informed purchasing decisions. As a buyer, you can easily compare the environmental impacts of different products, ensuring that your purchases align with your sustainability goals. Whether for individual use or as part of a corporate sustainability strategy, an EPD gives you the confidence that you’re choosing products with minimal environmental impact.

How Does Circular Economy Work?

A circular economy is designed to keep resources in use for as long as possible, reducing waste and making the most out of the materials and products we use. It creates value for businesses, benefits the environment, and improves outcomes for people.

For businesses, adopting a circular approach helps maximize the value derived from the resources you use, uncover new commercial opportunities, and lower operational costs. (That’s why it’s called a circular economy!)

It also helps businesses identify and manage risks while minimizing waste. But remember, a circular economy goes far beyond just recycling—it’s about rethinking product life cycles and creating a system where materials are continuously reused, refurbished, or remanufactured.

How Does Cradle-to-Cradle Work Instead of Cradle-to-Grave?

The cradle-to-cradle approach is the opposite of the traditional cradle-to-grave model. Instead of products having a life cycle that ends in disposal, cradle-to-cradle focuses on the continuous reuse of materials, ensuring products are designed to be regenerated rather than discarded.

Circular economy is built on three key principles:

→ Keeping products and materials in use

Materials and products are reused, refurbished, or remanufactured, ensuring their value is maintained over time.

→ Designing out waste and pollution

Circular economy goes beyond recycling—products are designed from the start to minimize waste and prevent pollution at every stage of their life cycle.

→ Regenerating natural systems

By returning resources to nature in a way that restores and enhances natural ecosystems, circular economy helps regenerate the planet’s resources.

This approach creates commercial opportunities that are not available in the traditional “take-make-dispose” linear economy, while also reducing the risks associated with it. The result is a more resilient, sustainable business model.

How Does Circular Economy Help Your Business?

Reduce Business Risks

A Circular Economy (CE) enables you to identify and manage supply chain risks, price fluctuations, and potential government levies on materials and finished goods. By adopting CE practices, you can stay ahead of regulatory changes and minimize these external risks.

Retain and Build Value

CE helps protect your intangible assets, such as intellectual property and brand reputation. It also ensures continued access to raw materials by recovering the value you’ve added to those materials. Additionally, CE can reduce costs by allowing you to retain value through reuse, recycling, and remanufacturing, strengthening your bottom line.

Please reach out to us for more details or if you like us to work with you on these matters. info@pathway2050.com